In recent times, 3D printing has transcended its origins as a distinct segment know-how and emerged as a disruptive drive in manufacturing, design, and innovation. From speedy prototyping to end-use manufacturing, additive manufacturing has revolutionized numerous industries, providing unprecedented flexibility, customization, and effectivity. On the forefront of this revolution are two distinct classes of 3D printers: hobbyist-level machines and industrial-grade techniques. On this complete information, we are going to discover the evolution of 3D printing know-how, look at the variations between hobbyist and industrial printers, and supply insights into when it is perhaps advantageous to transition from a hobbyist setup to an industrial powerhouse.

Understanding the Evolution of 3D Printing:

The origins of 3D printing will be traced again to the Eighties, with the invention of stereolithography (SLA) by Chuck Hull. This groundbreaking know-how paved the best way for additive manufacturing, enabling the layer-by-layer fabrication of three-dimensional objects from digital designs. Initially used primarily for prototyping functions, 3D printing step by step expanded its attain, with the event of recent supplies, processes, and purposes.

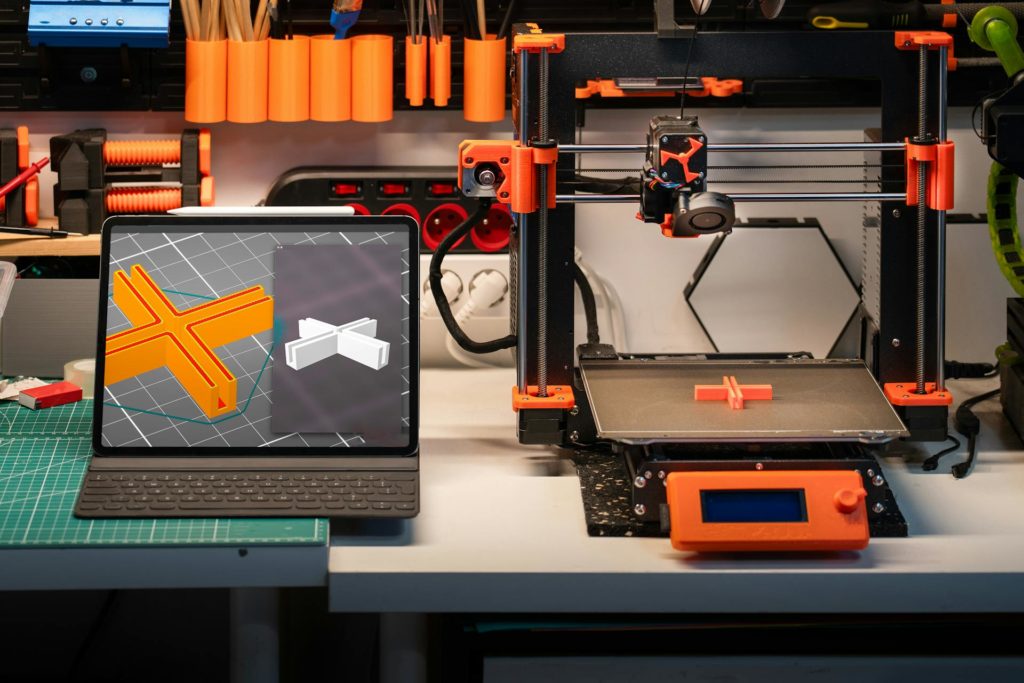

The early years of 3D printing have been characterised by excessive prices, restricted materials choices, and comparatively sluggish print speeds. Nevertheless, because the know-how matured and have become extra accessible, a brand new market emerged: the hobbyist 3D printing group. Hobbyist-level printers, typically primarily based on fused filament fabrication (FFF) or SLA know-how, supplied lovers, educators, and makers the chance to discover the world of additive manufacturing from the consolation of their very own properties or workshops.

The Rise of Hobbyist 3D Printing:

Interest 3D Printer: Picture Supply: trimech.com

The democratization of 3D printing can largely be attributed to the rise of hobbyist-level machines. These compact, reasonably priced printers opened up new potentialities for artistic expression, experimentation, and studying. Hobbyists might now deliver their concepts to life in tangible type, whether or not customized prototypes, customised gifts, or intricate artistic endeavors.

Hobbyist printers usually make the most of FFF know-how, which includes extruding thermoplastic filament via a heated nozzle to construct up layers of fabric. This course of is comparatively easy and simple, making it ultimate for newcomers and lovers. Equally, SLA printers use a liquid resin cured layer by layer utilizing a UV gentle supply, providing increased decision and finer particulars than FFF printers.

Challenges with Hobbyist Printers:

Whereas hobbyist-level printers have undoubtedly lowered the barrier to entry for 3D printing, they arrive with their very own challenges. One of many major drawbacks is print high quality and reliability. Hobbyist printers typically need assistance to take care of constant print high quality, leading to points corresponding to layer misalignment, warping, and floor imperfections. Customers might spend hours troubleshooting and fine-tuning their machines to attain passable outcomes, detracting from the general consumer expertise.

One other limitation of hobbyist printers is materials compatibility. Whereas they provide a variety of thermoplastic filaments and resins, hobbyist printers might not help specialised or high-performance supplies required for sure purposes. Moreover, hobbyist printers usually have smaller construct volumes, limiting the scale of objects that may be produced in a single print. This may be notably irritating for customers engaged on bigger initiatives or batch manufacturing runs.

The Promise of Industrial 3D Printing:

Industrial 3D Printer: Picture Supply: trimech.com

In distinction to hobbyist printers, industrial-grade 3D printers provide a degree of efficiency and flexibility that’s unmatched within the shopper market. These machines are designed for reliability, precision, and scalability, making them ultimate for a lot of skilled purposes. Industrial printers make the most of superior applied sciences corresponding to Selective Laser Sintering (SLS), Multi-fusion (MJF), or PolyJet, producing extremely detailed, advanced components with distinctive accuracy and floor end.

Key Concerns for Upgrading:

Making the transition from a hobbyist printer to an industrial-grade system is a major determination that requires cautious consideration. A number of elements must be taken into consideration when evaluating whether or not an improve is warranted:

1. Reliability: Industrial printers are engineered for steady operation and are geared up with options corresponding to automated calibration, lively temperature management, and superior print monitoring techniques to reduce the danger of print failures.

2. Precision: Industrial printers provide superior dimensional accuracy and floor end, permitting for the manufacturing of components with tight tolerances and complex geometries.

3. Materials Compatibility: Industrial printers help a variety of engineering-grade supplies, together with high-performance thermoplastics, steel alloys, and composite supplies, increasing the chances for practical prototyping and end-use manufacturing.

4. Construct Quantity: Industrial printers usually have bigger construct volumes than hobbyist machines, enabling the manufacturing of bigger components or batch printing of a number of elements concurrently.

5. Workflow Integration: Industrial printers are sometimes suitable with software program platforms and workflow administration instruments that streamline the design, preparation, and printing course of, lowering guide intervention and maximizing productiveness.

Case Research and Success Tales:

As an example the advantages of upgrading to an industrial-grade 3D printer, let’s discover a number of real-world examples of companies and organizations which have made the transition efficiently.

- Automotive Manufacturing: An automotive producer adopts industrial-grade 3D printing know-how to provide customized tooling, fixtures, and end-use components for its manufacturing line, lowering lead occasions and bettering general effectivity.

- Healthcare Innovation: A medical machine firm leverages industrial 3D printing to develop patient-specific implants and surgical guides, revolutionizing the sphere of personalised medication and bettering affected person outcomes.

- Aerospace Engineering: An aerospace engineering agency makes use of superior additive manufacturing methods to provide light-weight, advanced elements for plane and spacecraft, lowering weight, gasoline consumption, and manufacturing prices.

Greatest Practices for Implementation:

Transitioning to an industrial-grade 3D printing answer requires cautious planning and execution to make sure a easy integration into current workflows and processes. Key issues embrace:

1. Conducting a radical wants evaluation to establish particular necessities and goals.

2. Evaluating completely different printer fashions and applied sciences to seek out the most effective match to your utility.

3. Put money into coaching and help providers to make sure that customers are proficient in working the brand new tools.

4. Establishing high quality management procedures and efficiency metrics to observe and optimize print output.

5. Leveraging networking alternatives and business partnerships to remain knowledgeable concerning the newest developments and finest practices in additive manufacturing.

SelfCAD: Straightforward 3D Modeling for Rookies and Professionals

SelfCAD: Straightforward 3D Modeling for Rookies and Professionals: Picture Supply: selfcad.com

SelfCAD is a 3D modeling software program that helps folks create 3D fashions. You should utilize it in your internet browser or obtain it to your laptop. It doesn’t matter when you’re simply beginning out or when you’re already a professional at making 3D fashions – SelfCAD is for everybody. It’s designed to be simple to make use of, so even newcomers could make cool 3D stuff with out a number of trouble.

There are many assets out there that will help you learn to use SelfCAD. You’ll be able to watch movies, observe interactive tutorials, or learn detailed guides. And when you ever get caught, there’s loads of assist out there.

The most effective options of SelfCAD is its slicing software program. This allows you to get your designs prepared for 3D printing, so you may flip your digital creations into real-life objects. However that’s not all – SelfCAD additionally has instruments for sculpting, sketching, and rendering. You’ll be able to even begin with pre-made shapes and customise them to make one thing completely distinctive.

In the event you’re extra into 2D drawing, SelfCAD has you coated there too. You’ll be able to draw sketches and switch them into 3D fashions with just some clicks. And when you’ve made one thing superior, you may simply share it with others and work collectively on initiatives.

SelfCAD gives completely different pricing plans to suit your wants. There’s a free plan that allows you to make and export three drawings each month. In the event you want greater than that, you may join a paid subscription beginning at $14.99 per 30 days. With a paid subscription, you get limitless entry to all of SelfCAD’s options, together with exporting, 3D printing, and rendering.

So whether or not you’re a complete newbie or a seasoned professional, SelfCAD has every part you have to deliver your 3D creations to life. Give it some effort and see what you may create!

Conclusion:

As a complete, the event of 3D printing marked a brand new period full of creativity and alternative. Whereas hobbyist-level printers have performed a vital function in democratizing entry to additive manufacturing know-how, they is probably not appropriate for demanding skilled purposes. Industrial-grade printers provide unparalleled efficiency, reliability, and flexibility, empowering companies to unlock new alternatives and drive innovation. By rigorously evaluating the precise wants and objectives of your group and leveraging the experience of business professionals, you can also make a well-informed determination that positions you for fulfillment within the quickly evolving world of additive manufacturing.